Our innovative Orchid Tray offers an eco-friendly solution to floristry, combining ease of use with stylish, efficient design for beautiful displays.

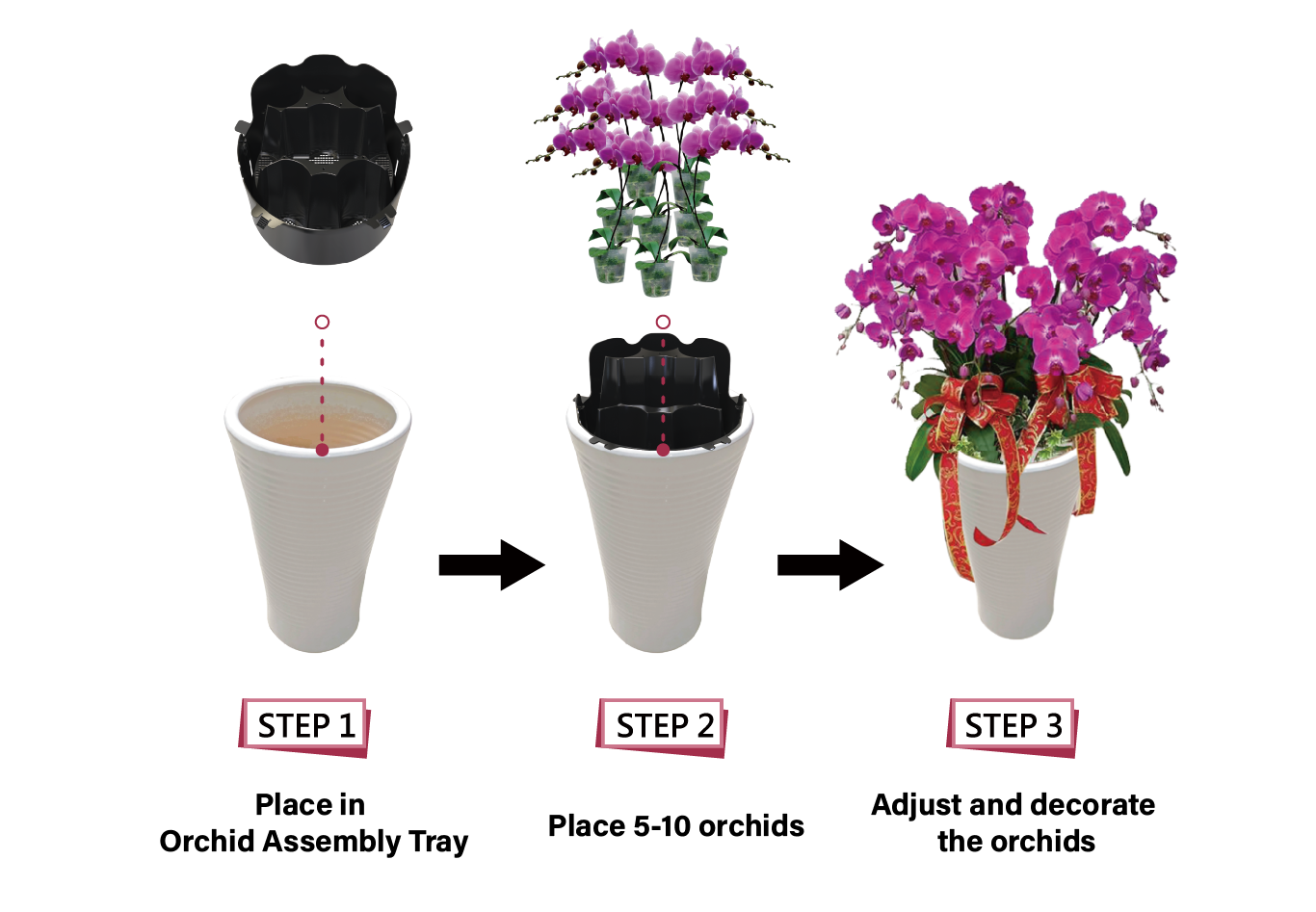

▶ Quick Orchid Pot Assembly

▶ Cuts Assembly Costs by 45-50%

▶ Eco-Friendly, EPS-Free

▶ Less Stakes Needed

▶ Optimizes Storage Space

▶ Reduces Aquatic Weed Usage

▶ Over 10kgs Weight Capacity of Flower Assembly Tray

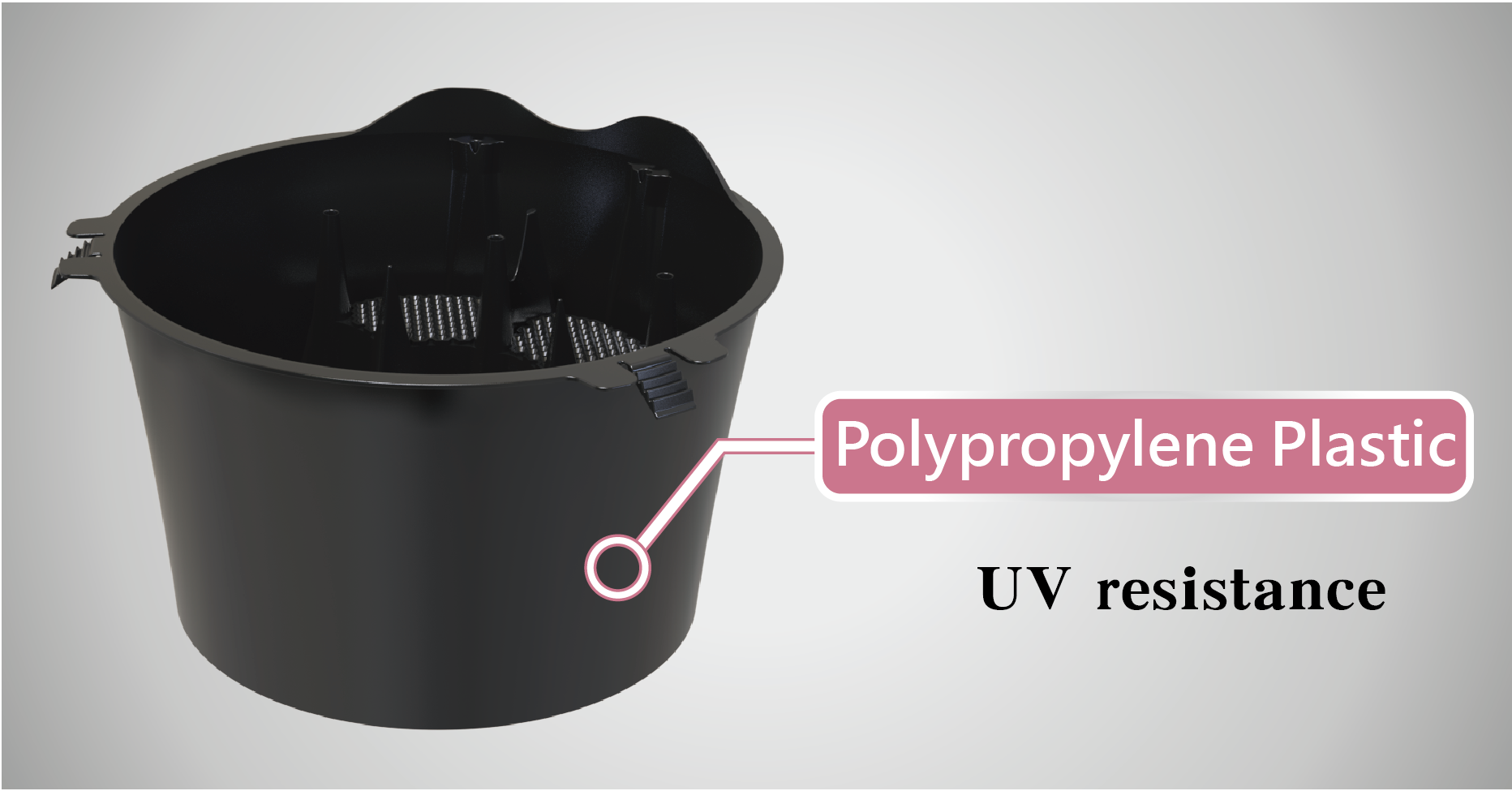

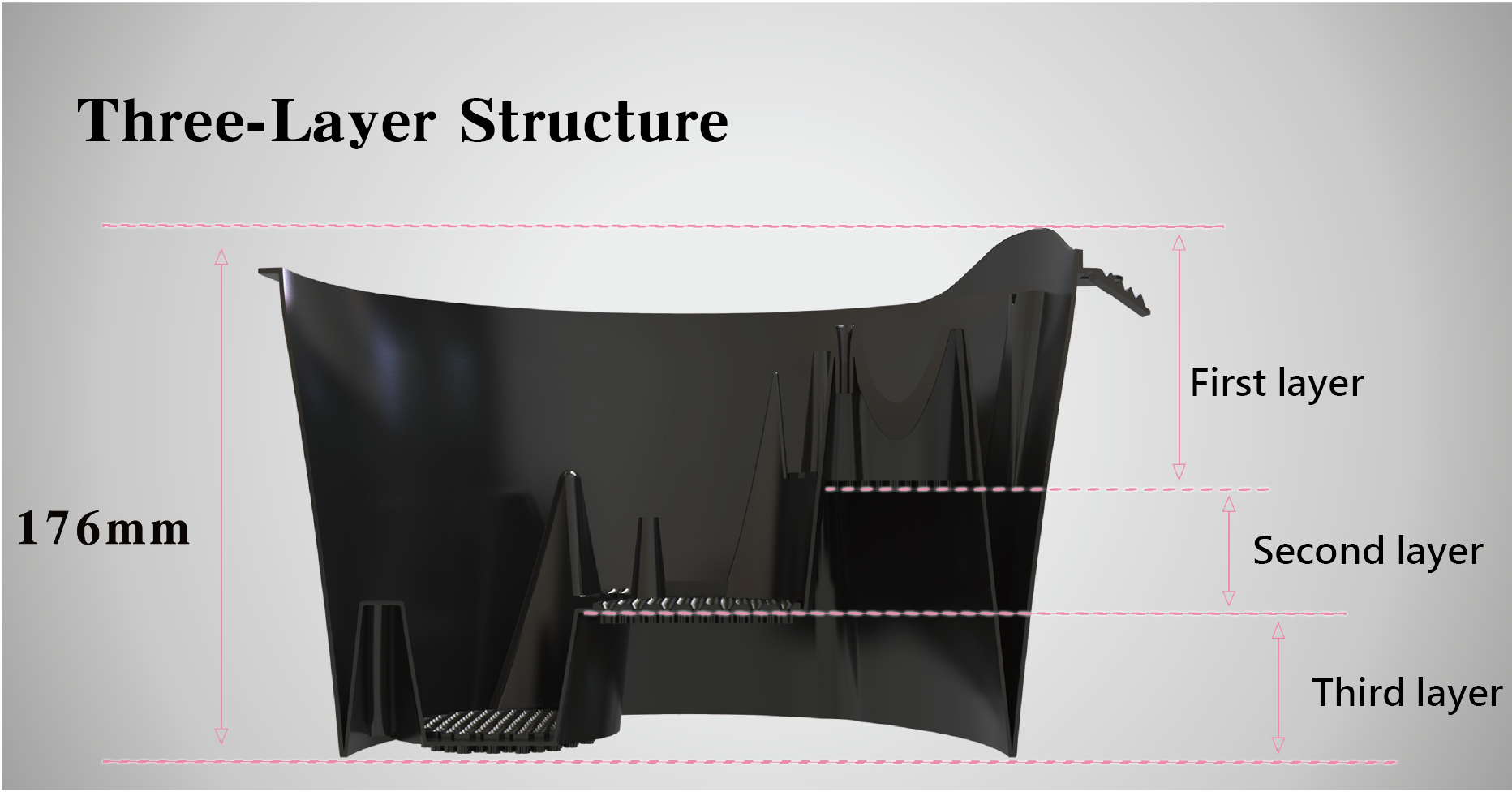

Made of high-toughness polypropylene material, renowned for its durability, the orchid stand boasts a prolonged lifespan, high weight-bearing capacity, and UV resistance without becoming brittle.

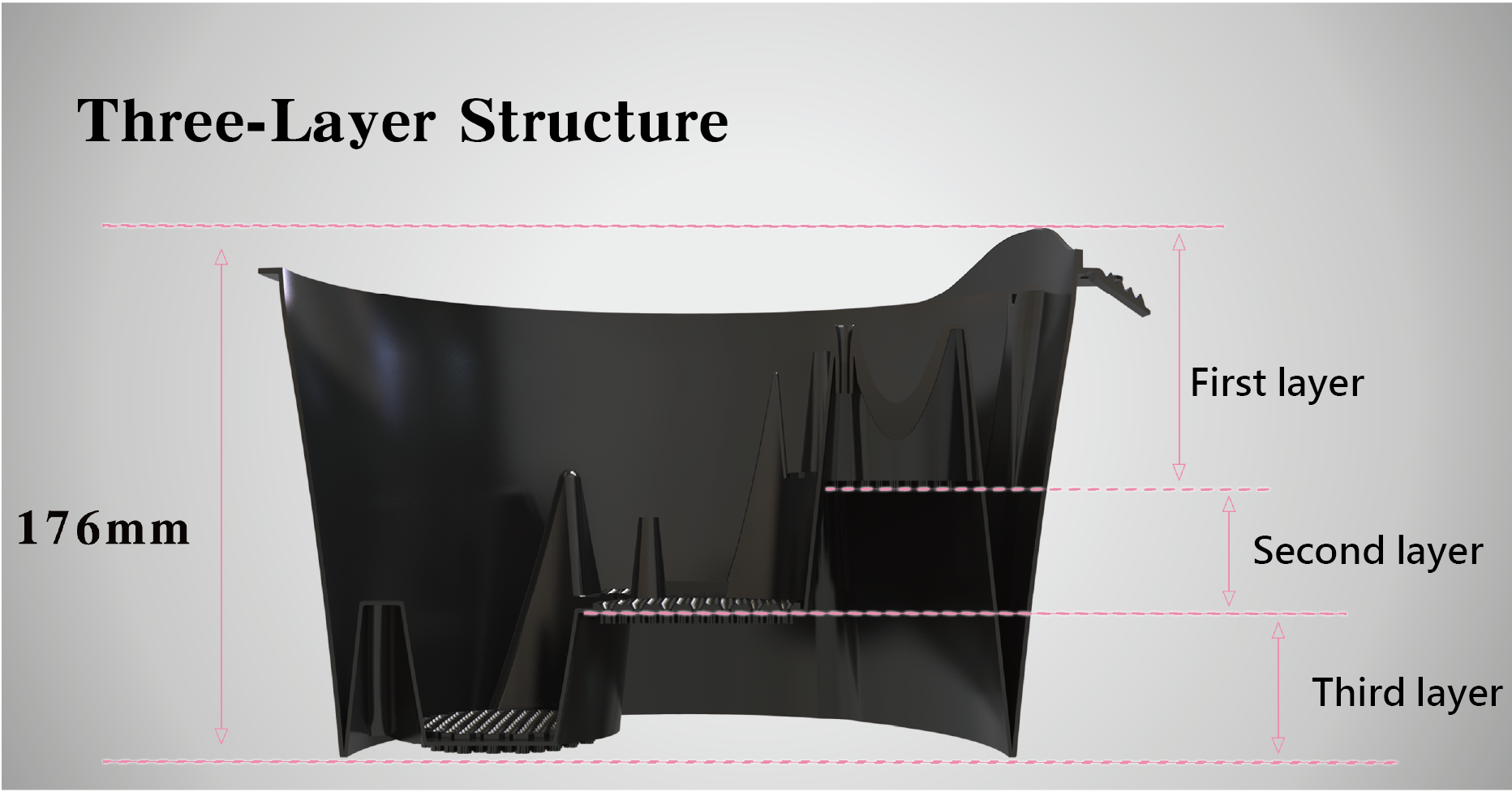

▶ Three-Layer Structure: Effortlessly Create Layered Aesthetics

Featuring a tiered bottom design, this orchid assembly stand eliminates the need to fill the EPS in the porcelain pot, allowing orchid designers to effortlessly place and adjust orchids to their desired height and direction.

▶ Dedicated Stake Holes: Sculpting Perfect Flower Shapes

The stake holes assist in supporting orchid stems upright, facilitating easy sculpting for perfect flower shapes, enhancing the overall elegance of the orchid gift pot.

▶ Honeycomb Bottom Design: Enhances Design Flexibility

The stake holes are also applied at the bottom of each layer, enabling the florists to insert the stake at any place they want, enhancing flexibility.

▶ Solid Outer Shell

The solid outer shell of the orchid assembly tray prevents the scattering of orchid plant residues (such as moss or wood chips) during transportation or handling.

▶ Three-Elastic Devices & Snap-Fit Design

The orchid assembly tray is also equipped with three elastic devices to ensure that the tray is securely fastened inside the flower containers.

▶ Four Size to Fit Most Orchid Pots

Zhu Xing has developed four sizes of orchid assembly tray compatible to diverse range of circular diameters porcelain pots.

▶ Stackable Structure, Minimizing Storage Space

This innovative design of the orchid assembly tray is stackable, minimizing storage space requirements.

I. Revolutionizing Products And Business Opportunities.

The Commercial Phalaenopsis gift pot-making industry has relied on a labor-intensive assembly method for the past 20 years. However, now it faces various challenges related to environmental awareness, inflation caused by the Covid-19 pandemic, a shortage of foreign workers, a decline in young people's participation, and a gap in new florist training. This study aims to identify innovative solutions to overcome these challenges. As global environmental problems worsen, the use of expandable Polystyrene (EPS) and porcelain pots in Phalaenopsis gift pots is becoming a concern. Porcelain pots are not recyclable, and EPS is bulky, making recycling less cost-effective for recyclers and has made them unwilling to collect EPS. As a result, disposing of the porcelain pots and EPS becomes trouble for consumers when the flowers wilt. The industry in Taiwan uses approximately 6,000 tons of porcelain pots and requires about 23,800 cubic meters of EPS annually. The inflation caused by the pandemic has significantly increased various costs for the Phalaenopsis gift pot industry. However, the rising costs are only marginally reflected in the selling price due to fierce competition in the flower market. This has drastically reduced profit margins for many businesses, making it difficult to operate. The pandemic has directly caused a shortage of foreign workers in the industry. Additionally, it has indirectly accelerated a shift in societal values, with younger generations prioritizing personal fulfillment over job success or financial gain. Consequently, young people are less willing to work overtime or in labor-intensive industries. This has resulted in a gap in training for new florists. The study proposes two innovative solutions: the "Orchid Assembly Tray" and the "Detachable Flower Stand." The innovative solutions were tested by research participants and demonstrated their effectiveness in addressing the difficulties and challenges faced by the Phalaenopsis gift pot-making industry.

II. The Industry's Challenges

▶ Challenge One

Rising Eco-consciousness among consumers

▶ Challenge Two

Material Cost Increase

▶ Challenge Three

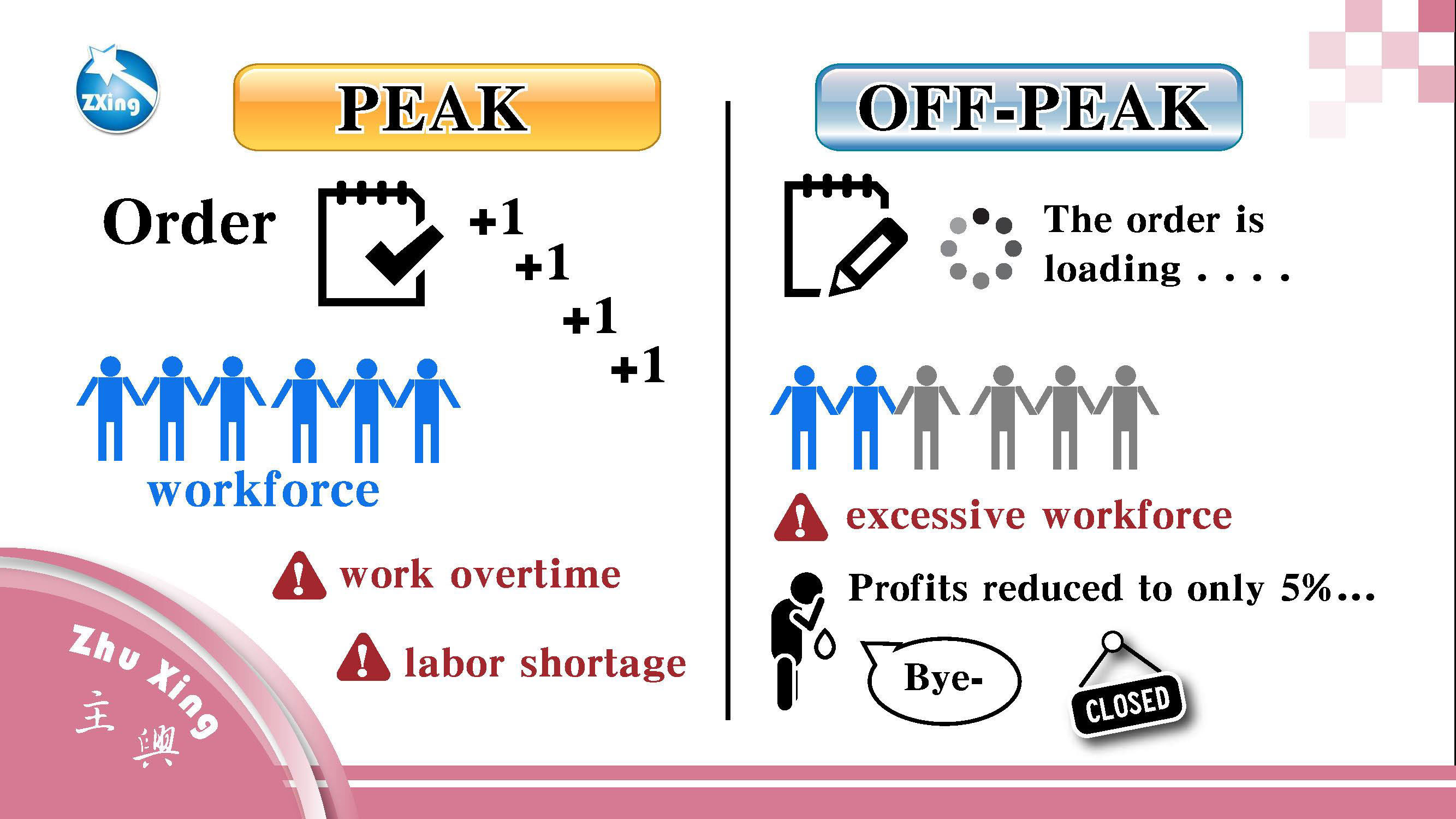

Labor Shortage Problem during peak season and Excessive workforce in Off-Peak season

▶ Challenge Four

Gap in training young florists

III . Innovative Solutions

▶ Orchid Assembly Tray

▶ Detachable Flower Stand

In Taiwan, as many of you may know, we have a tradition of giving large Phalaenopsis pots as gifts to show gratitude and goodwill towards friends, relatives, or business partners.

It was five years ago, right around the Chinese New Year. Our office was graced with several splendid orchid pots.These vibrant orchids instantly captured the attention of every passing colleague, filling the office with a delightful festival atmosphere.

These arrangements, often including 5 to 9 plants, could stand as tall as 120cm.

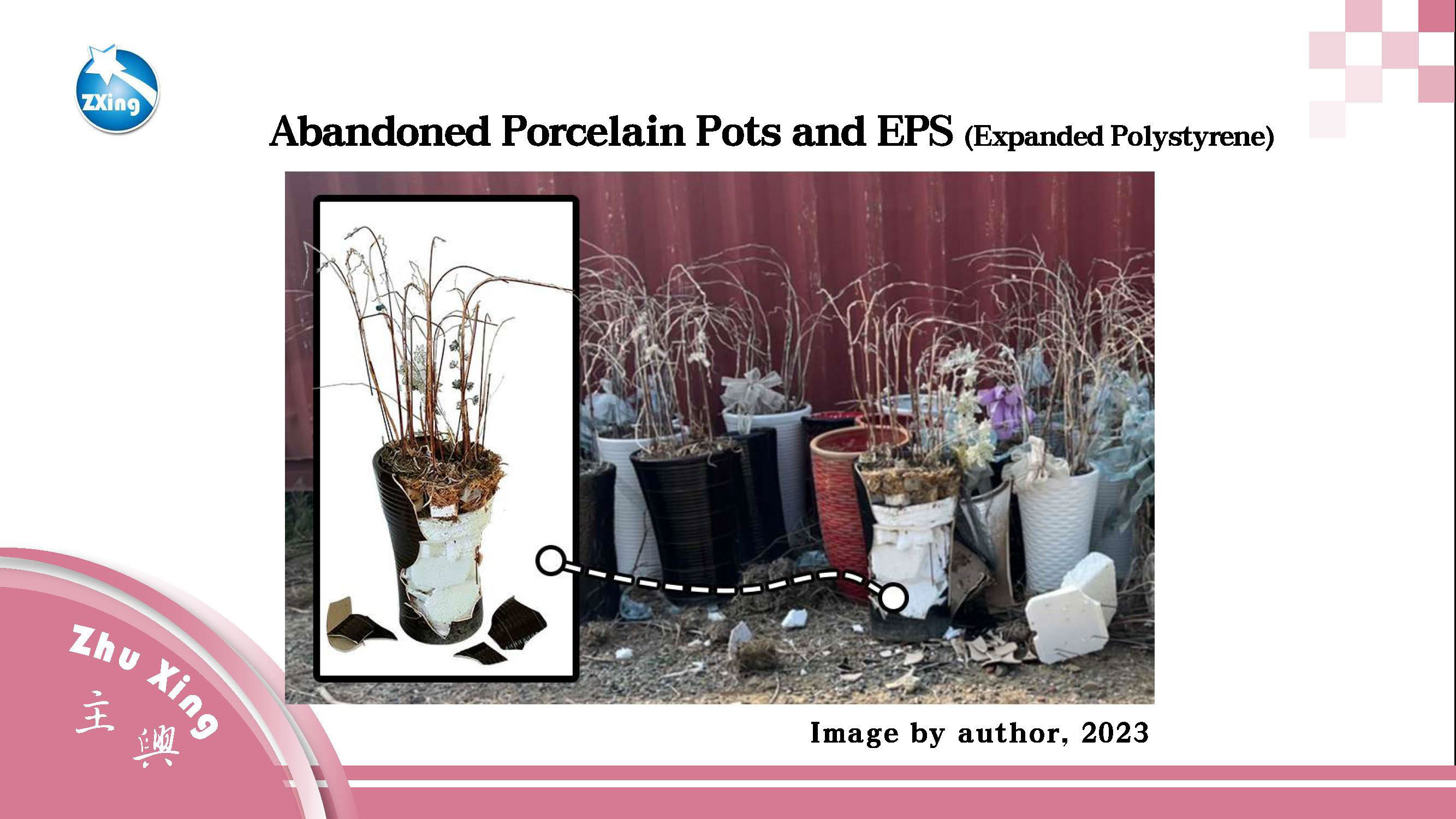

But then, reality hit.The flowers wilted, leaving us with disposal troubles that made us wonder if we were the part-time waste handlers.

These pots were filled with expanded polystyrene, commonly known as EPS, to support the plants at top of the pot. Since EPS was contaminated with soil and plant residues, it couldn’t be recycled and became general waste. As for the porcelain pots, if they weren’t in perfect condition for flower shops to reuse, they are regarded as industrial waste with disposal fees.

Although we always managed these wilted orchid pots responsibly, it was distressing to see that not everyone did the same - many wilted orchid pots were abandoned in alleyways or less populated areas, leading to many environmental concerns.

It was during this time that I wondered: "Isn't there a more eco-friendly way to deal with this?” A more creative, more ideal, more innovative solution to solve this issue.

So, we spoke with industry experts to understand their current challenges. These challenges include a rising eco-consciousness among consumers, increasing costs, labor shortage, and a gap in training young florists.

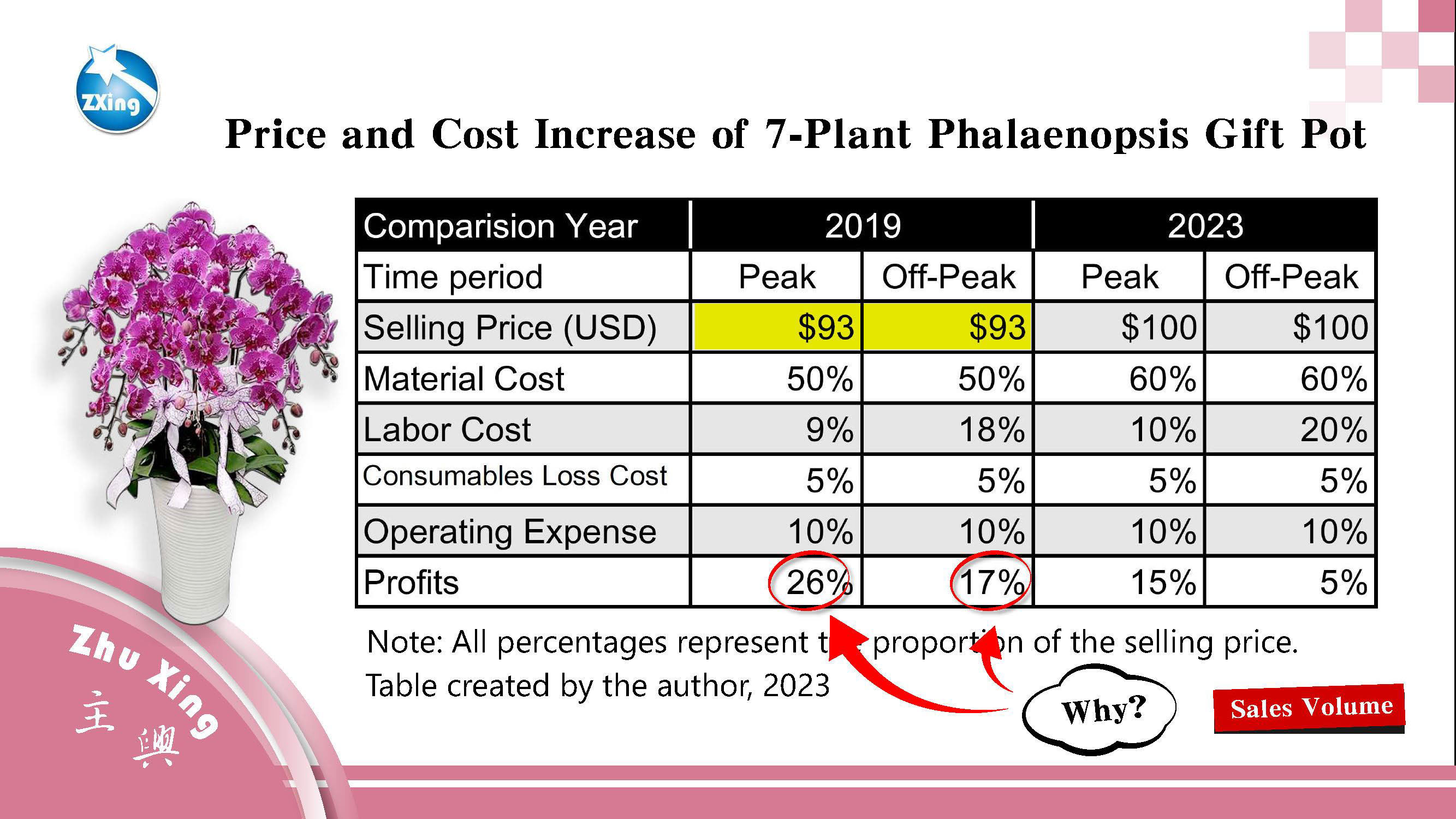

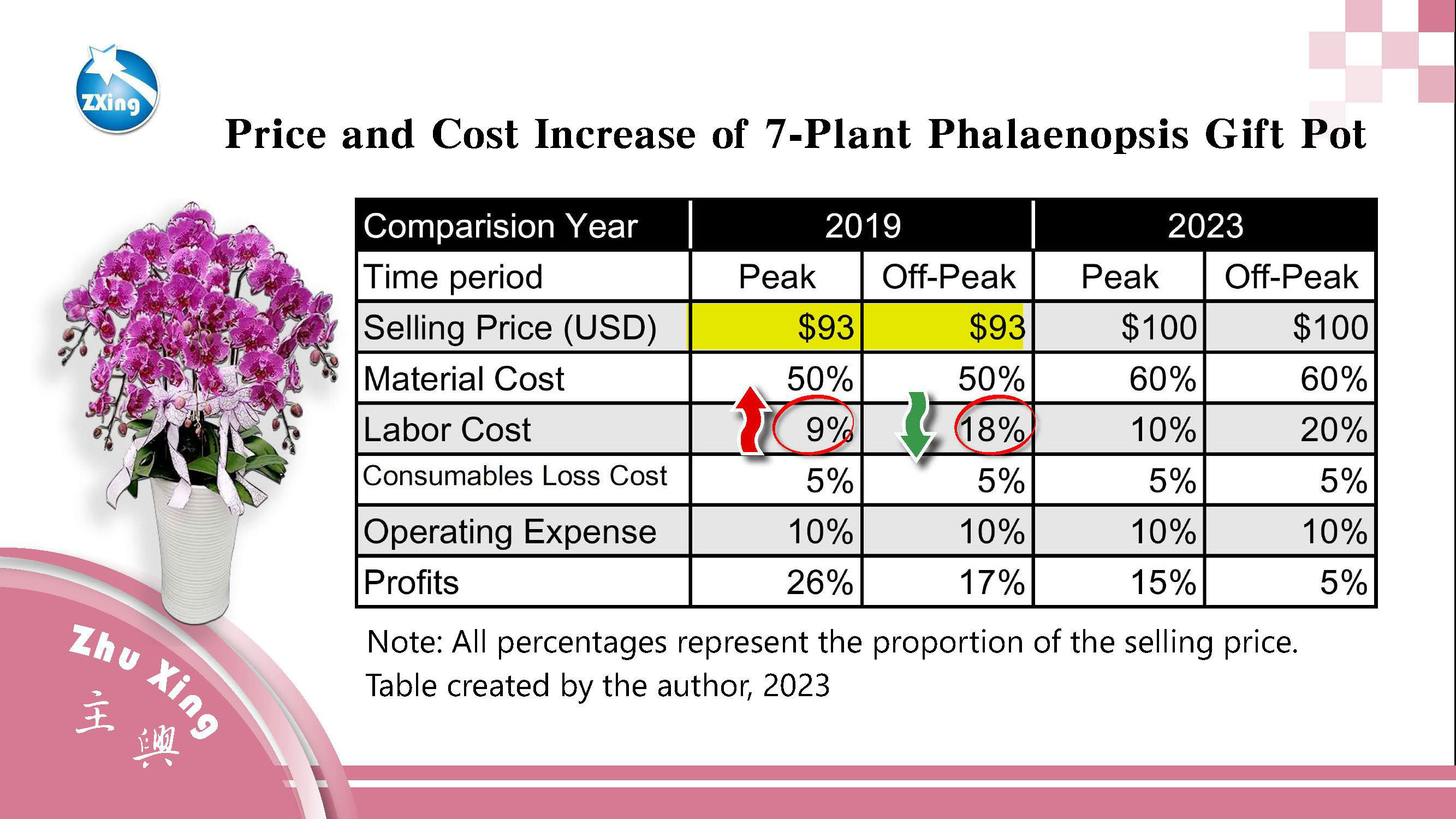

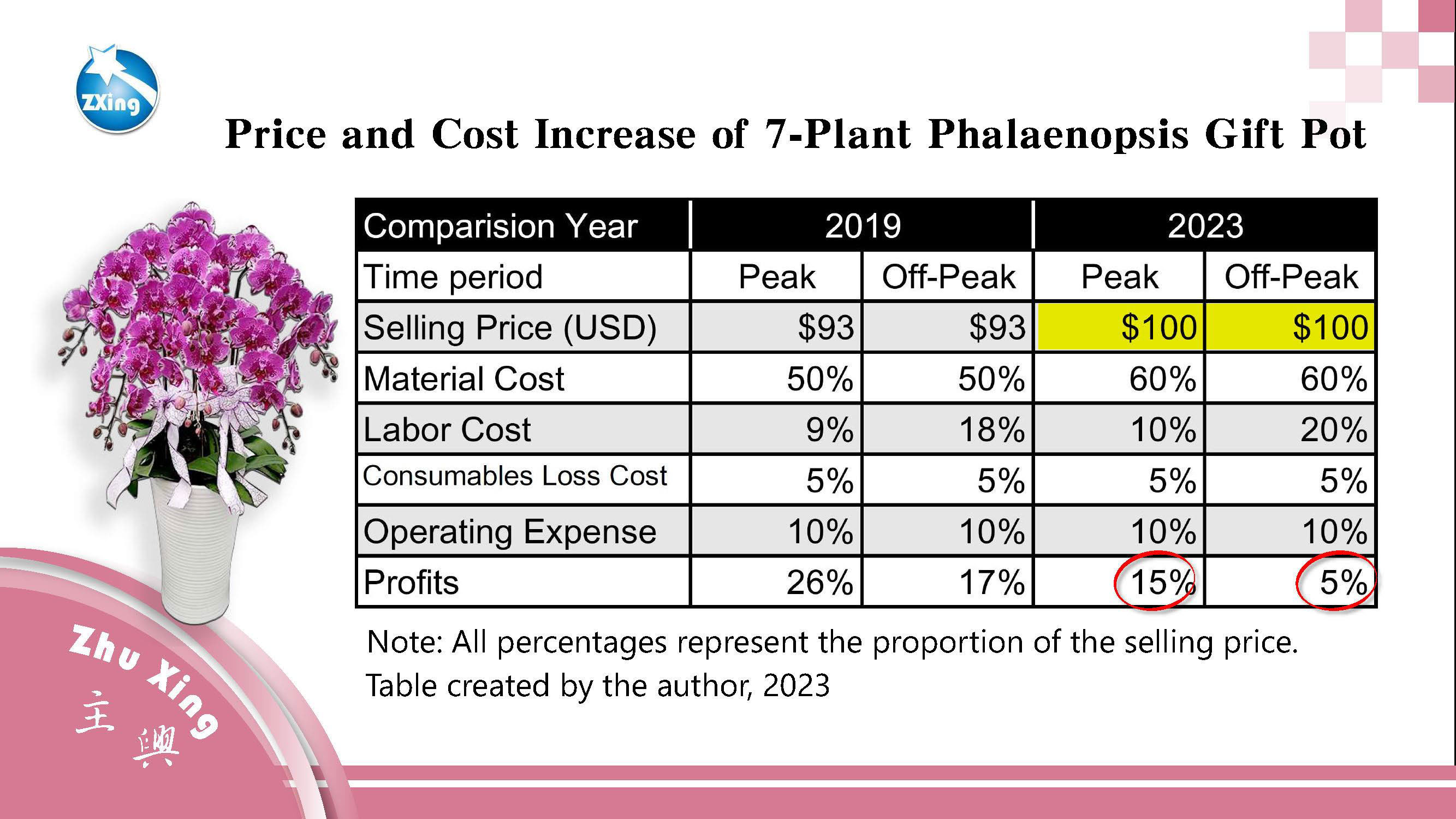

This table outlines the shifts in price and cost structure for a seven-plant Phalaenopsis gift pot.Note that all percentages here represent the proportion of the selling price.

Let’s get back in 2019, the selling price was around 93 US dollars, with 26 percent profit in peak seasons and 17 percent profit in off-peak seasons. You might want to ask “why is there such a big difference between peak and off-peak seasons?” The key factor is sales volume.

High sales volume in peak season led to lower average labor costs – only 9 percent, but the labor costs doubled to 18 percent in off-peak season due to lower sales volume.

Moving to 2023, despite an increase in the selling price to about 100 US dollars, material costs soared to 60 percent of the selling price. As a result, profit margins dropped to 15 percent in peak seasons and a meager 5 percent in the off-peak seasons. Here I’d like to explain that unlike daily necessities, this is a market filled with alternatives such as other flowers, fruits, or even cookie gift boxes. It's challenging for businesses to raise prices enough to offset these increases. Consequently, businesses often had to absorb most increasing costs by themselves.

This slide illustrates the contrast between peak and off-peak seasons. During peak seasons, we see a surge in orders, leading to inevitable work overtime and labor shortage. Conversely, during the off-peak seasons, the market slows down with far fewer orders, resulting in an excessive workforce. As explained in the previous slide, by 2023, the profit margin during off-peak seasons had shrunk to a meager 5 percent, barely covering basic operational expenses. In such a competitive market, some businesses were compelled to shut down.

We often encounter a common blind spot. You cannot have both.

Boosting productivity while hiring fewer people seems impossible.

Maintaining design flexibility while simplifying the assembly process seems contradictory. Creating a stunning display without extending assembly time, using recyclable materials while cutting costs, increasing profits while improving wages — these appear to be conflicting goals.But are they really conflicting goals? Can‘t we have both? Can’t we find a way to have it all?

The answer is "Yes". What we need is an innovative solution.

Therefore, we did market research to understand the requirements of the businesses and the floral designers. Then our R and D team kept brainstorming and disappearing for two years.

After two years, they emerged, slightly older and out of charge, but finally proposed two innovative products. The orchid assembly tray and the detachable flower stand. Let’s first take a closer look at the orchid assembly tray, both made of recyclable polypropylene plastic.

Our R and D team designed this tray as a substitute for the EPS to support orchid plants at the top of pots. The prototype is a basket to be placed at the edge of the porcelain pot.

The tray features a three-layer structure, with each layer being approximately 10 centimeters apart in height.

Each layer includes cup-shaped structures to hold 3 point 5 inch orchid plants, enabling florists to easily place and adjust the orchids to their desired direction and height.

Additionally, the tray integrates stake holes to support the long orchid stems upright.

The stake holes are also applied at the bottom of each layer, giving the florists the freedom to poke the stakes at any place they want, enhancing the design flexibility.

The design is also stackable, greatly saving storage space.

Furthermore, it is equipped with three elastic devices to ensure it is securely fastened inside the flower containers, enhancing stability.

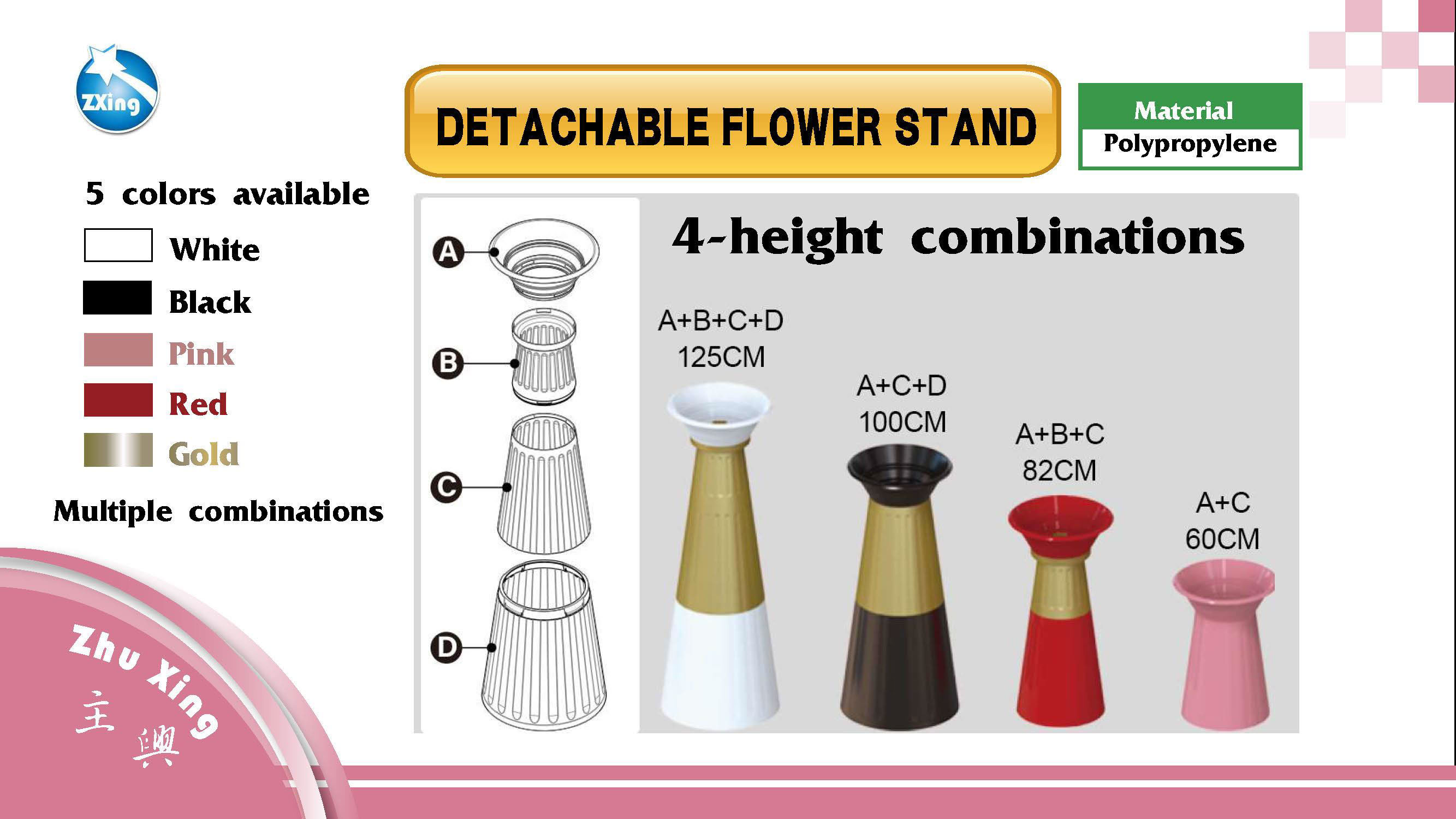

After addressing the issues with EPS, we shift our attention to the challenges posed by porcelain pots, which include their fragility, heavy weight, large storage requirements, high transportation costs, and waste disposal concerns. To overcome these challenges, our R and D team proposed the Detachable Flower Stand, which consists of four parts as illustrated in the line drawing. These four parts can be assembled into 4 heights and are available in 5 colors, offering a range of creative color combinations for display.

Parts A, C, and D can be individually stacked to save storage space. For transport convenience, these parts can also nest within each other, making it easier for movers to carry. Additionally, the flower stand is designed to be flipped for use too, as shown on the left of the slide, offering a different display option.

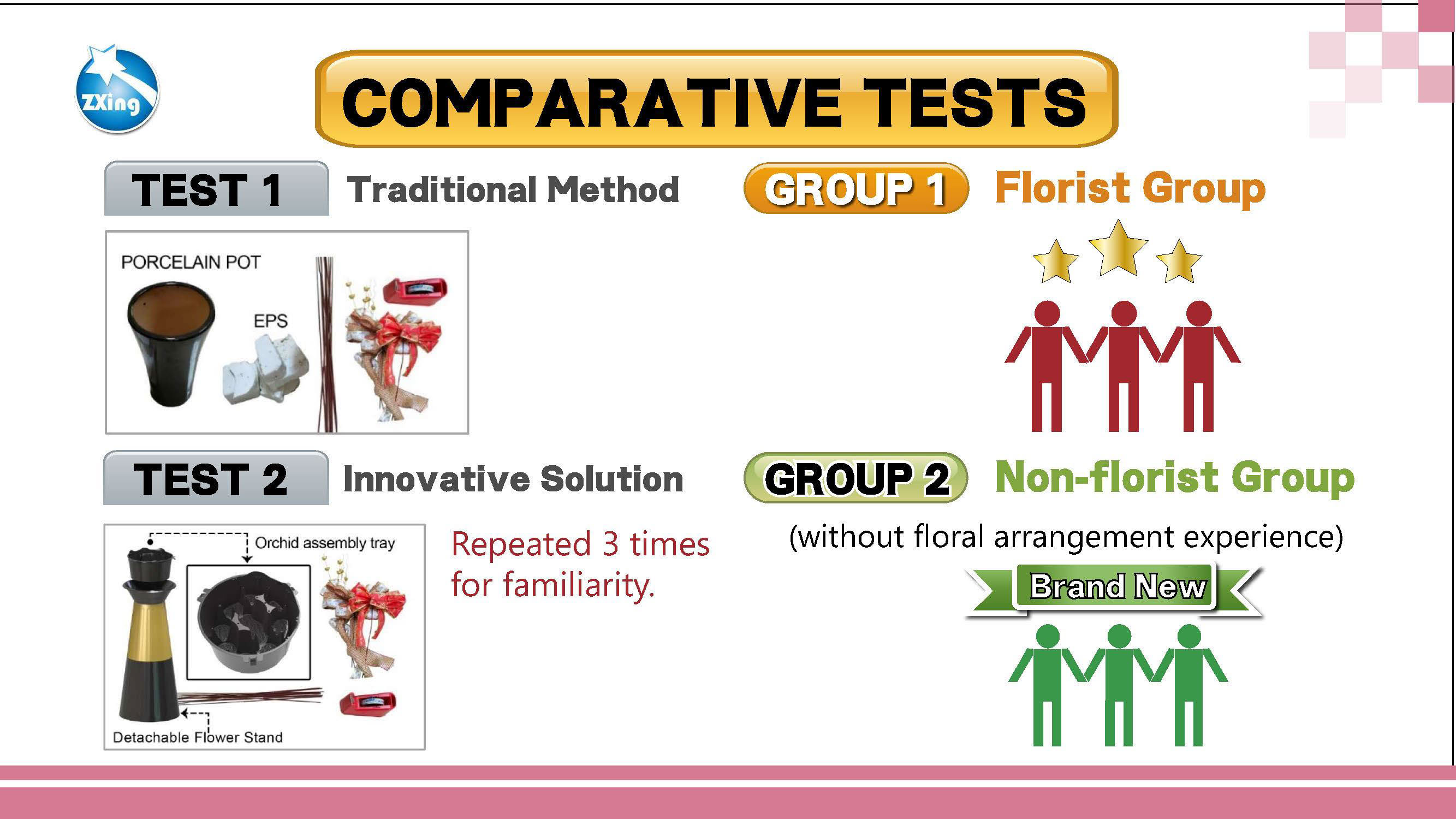

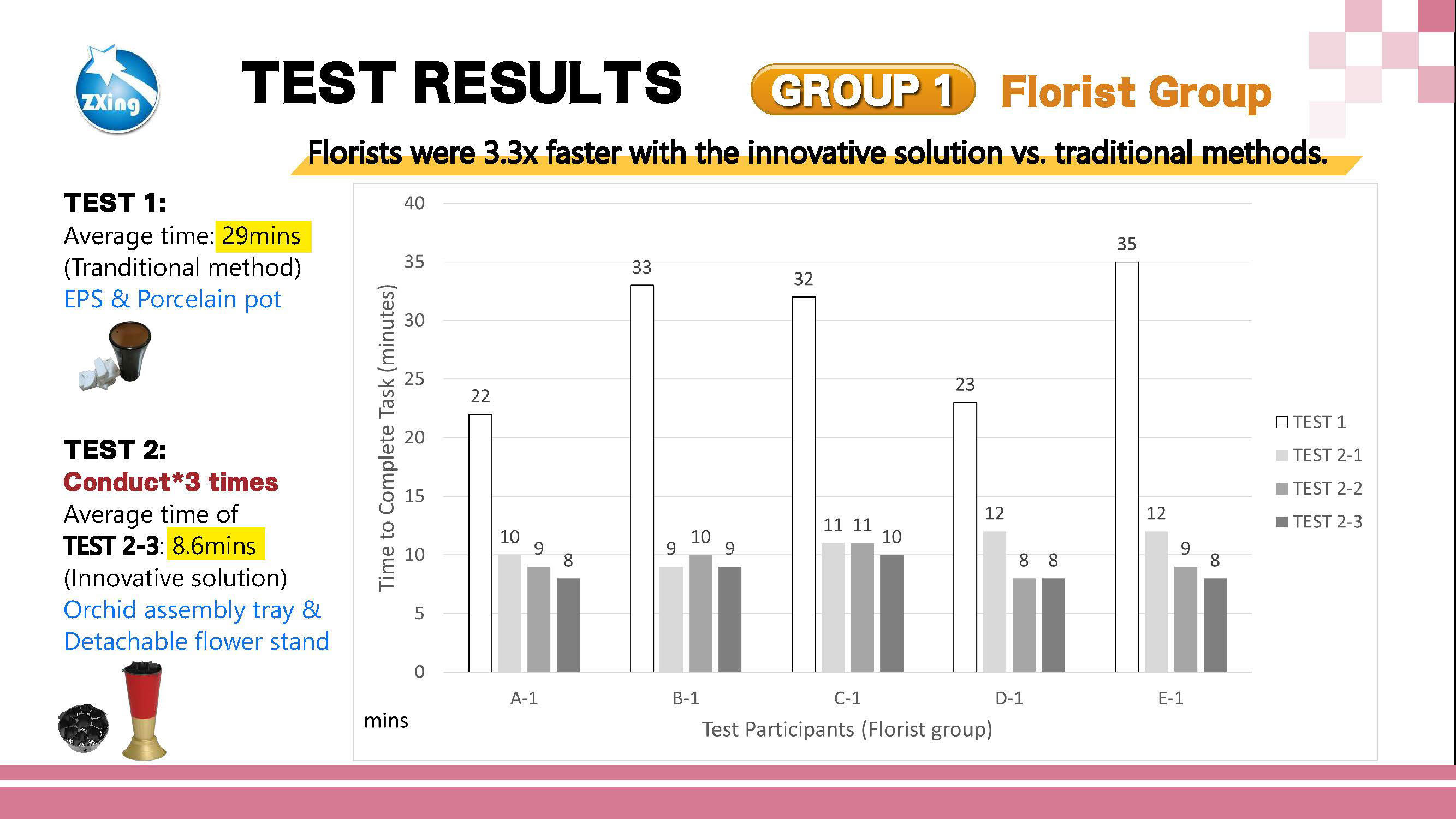

This study implemented comparative tests to evaluate efficiency with the traditional method against the innovative solution. On the left, you can see the different materials used in each test. Test 1 used traditional EPS and porcelain pot. Test 2 used the innovative assembly tray with detachable flower stand. Kindly note that test 2 was conducted three times to ensure that all participants were familiar with the innovative tools, thus providing a fair comparison of the assembly time.

To the right, we divided the participants into two groups. Group one: our professional florists with shining stars above the head. Then, there is group two: the brand-new individuals without floral arrangement experience. These participants were recruited from five research entities, labeled as companies A through E. Each research entity designated a professional florist and a non-florist individual.

Here we have the performance results of our florist group. The vertical axis shows the assembly time, while the horizontal axis lists our participants from five research entities. The white bars represent the time taken to complete Test 1 using the traditional EPS and porcelain pot. The gray bars indicate the assembly time for Test 2, conducted three times with our innovative solution.

On average, Test 1 took 29 minutes. By the third conduction of Test 2, the average assembly time was reduced to just 8 point 6 minutes. This demonstrates that our florists were 3 point 3 times faster with the innovative solution than with the traditional methods.

Here are the artwork displays of test 1 and test 2 created by the florist group. In test 2, we use Detachable Flower Stand, containing part A, C, and D. The overall height with orchids can reach about 170cm. Thus, it looks much higher than the potted one.

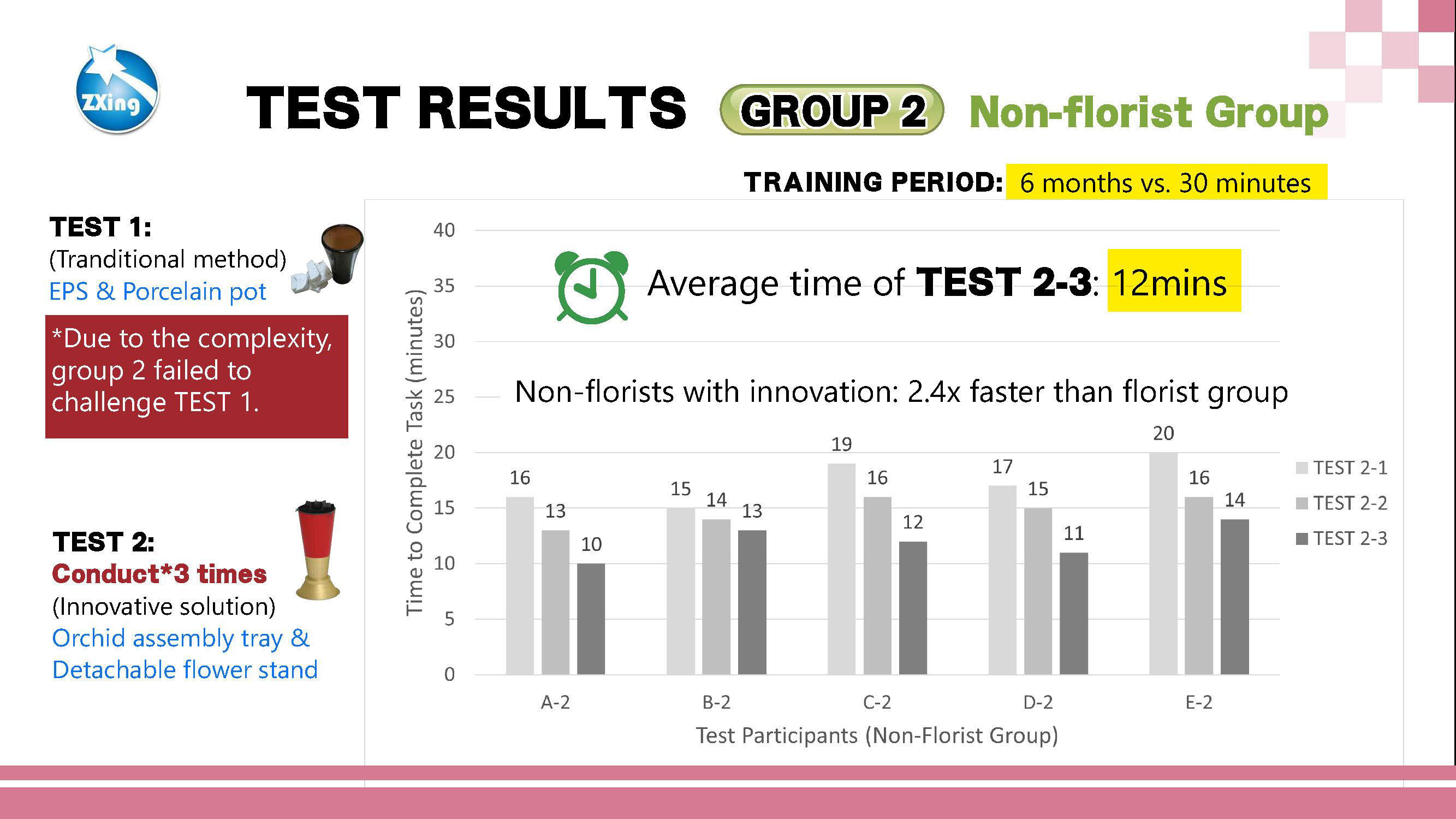

Now let’s see the performance of our non-florist group. Notably, due to the complexity of the traditional assembly method, the non-florist group failed to challenge test 1. Therefore, it shows only the gray bars of test 2.

For your information, the training period for beginners traditionally took around 6 months. With the innovative solution, the beginners can quickly get familiar with the assembly in just 30 minutes.

Remarkably, the average time of the third conduction of test 2 is 12 mins, which is 2.4 times faster than the florist group using the traditional method.

Here are the artwork displays of test 2 created by the beginners after just 30 mins training, so you can imagine how it will be after one hour or one day training.

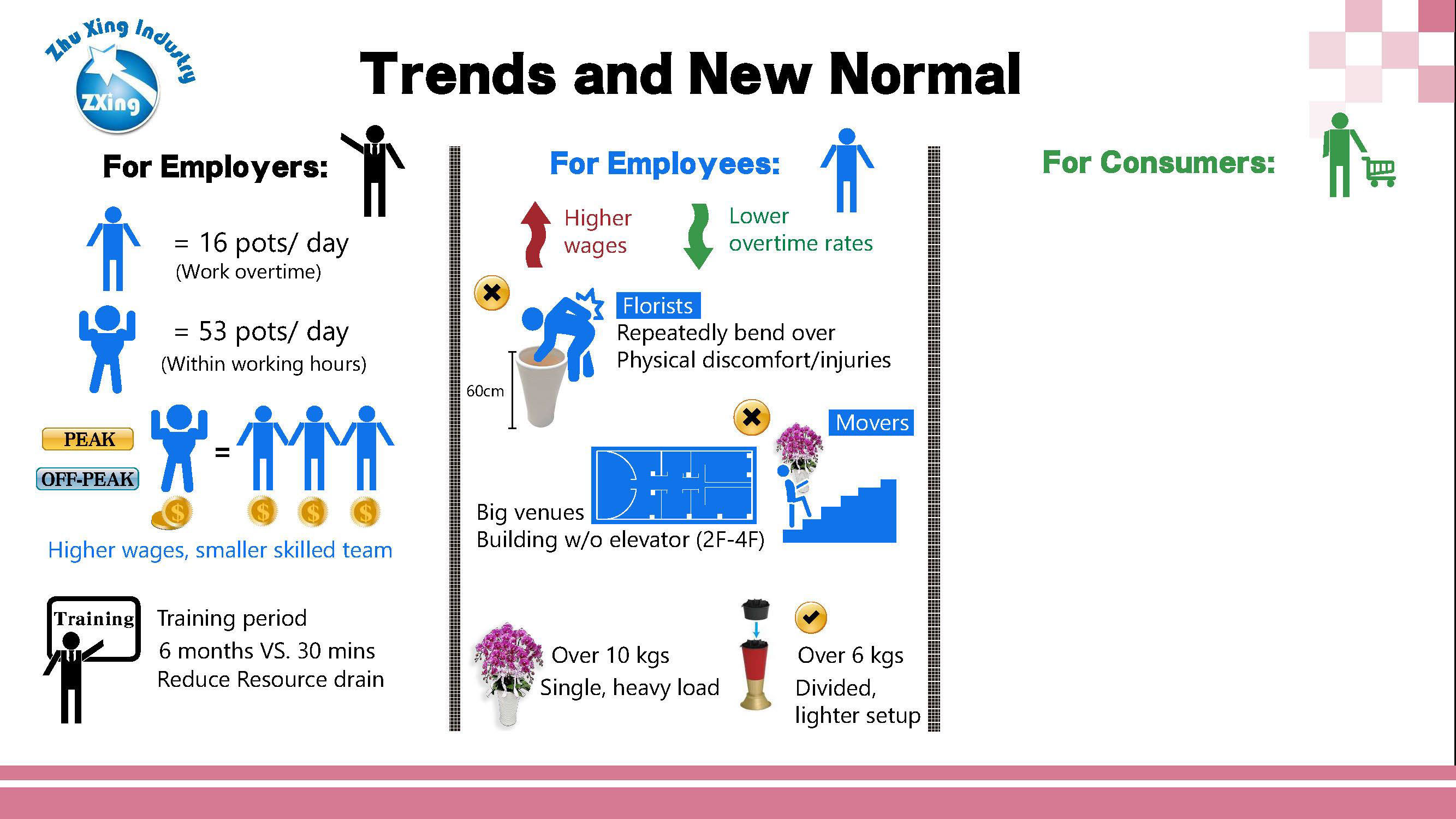

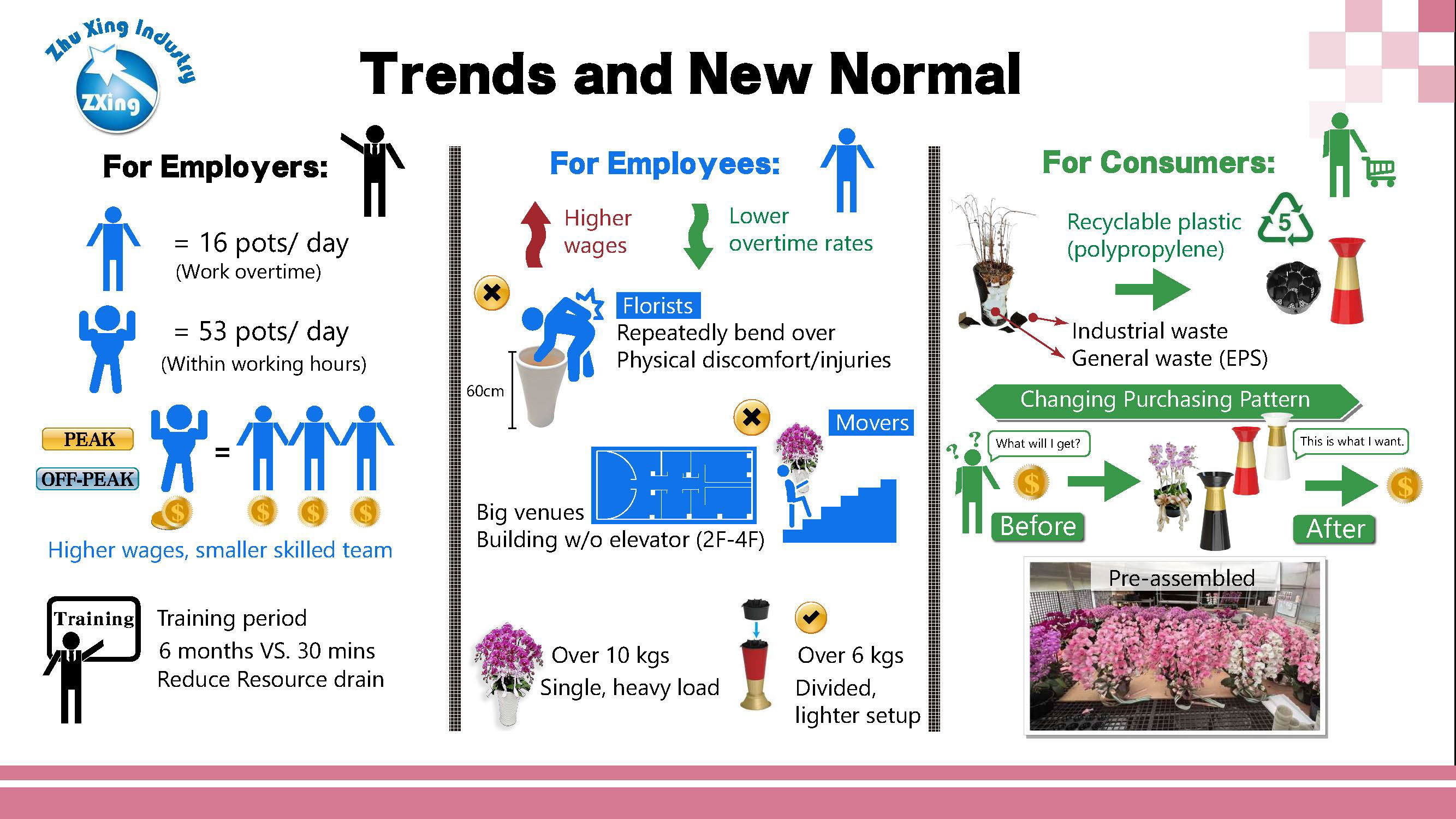

Let's have a quick review and explore the new trends and new normal brought by our innovative solution, covering three key segments.

For employers, the future is about efficiency. Previously, a worker could handle only 16 pots a day, and often had to work overtime. But now, look at them! With the innovative solution, they are like superheroes in the potting world, managing 53 pots a day, within regular working hours, leaving work with energies to enjoy their evenings. This addresses the labor shortage problems during peak seasons and the excessive workforce in off-peak seasons, moving towards a smaller, better paid, and more skilled team.

Additionally, the training period is reduced from half a year to just half an hour, saving significant company resources.

For employees, the benefits are clear- higher pay, less overtime rates and no more back-breaking work of filling the porcelain pots with EPS. For your information, the porcelain pots are typically 60 centimeters in depth. Florists need to bend over repeatedly to fill the pots with EPS, which causes the waist and shoulder discomfort. Movers also benefit, as they no longer need to carry over a 10kg flower display as a unit in large venues or buildings without elevators. Now, they can first set up lighter flower stands at the appointed positions and then simply place the pre-assembled flower displays at top of the pot. This significantly reduces physical strain, creating a more worker-friendly environment.

For consumers, our innovative solution brings two key changes. Firstly, it effectively addresses waste disposal problems associated with traditional flower displays.

Secondly, it changes how large Phalaenopsis gift pots are purchased.

Let‘s delve deeper into this. In Taiwan, the choice of porcelain pots varies by occasion. For example, black for funerals, red for events like elections or opening ceremonies.

Typically, designers first select a pot suitable for the occasion, fill it with EPS, and then arrange the flowers. This makes pre-assembly bulky and impractical. As a result, consumers often make the purchase without a clear idea of how the final product will look like.

Please direct your attention to the picture in the bottom right. This picture displays pre-assembled flower arrangements using orchid assembly trays. Consumers can customize their flower stands by selecting the height and their preferred color combinations. This approach enables a clear visualization of the product before purchase, greatly enhancing the buying experience.

Over time, these trends will define the new normal, establishing a more efficient, employee-friendly environment that attracts young talent, creating an environmentally conscious landscape in the Phalaenopsis gift pot-making industry.

Now, it's showtime. Here are the masterpieces created by our customers, showcasing the vibrant orchids and versatility of our detachable flower stands. They are my personal favorite. Hope that you like them too.

These splendid orchid displays are used for opening celebrations.

They are also suitable for outdoor activities

This is the display for indoor ceremonies.